With accurate reorder points for all of your product SKUs, you can meet customer demand in a timely fashion to improve cash flow and avoid the bloated costs of overstock. When you use data to forecast demand, you can set informed reorder points so you aren’t left without inventory during https://www.facebook.com/BooksTimeInc/ times of increased customer demand. The more you calculate ROP for each product, the more accurately you can forecast demand in the future and ensure you use the reorder quantity formula correctly.

CompanyCompany

- In other words, it’s the point at which you need to reorder more inventory to keep up with demand which helps to avoid stockouts and keep your business running smoothly.

- When the inventory balance declines to 100 units, ABC places an order, and the new units should arrive four days later, just as the last of the on-hand widgets are being used up.

- This means increasing the next order to replace it (one of the many pitfalls of working with inaccurate data).

- By keeping track of average delivery lead time, you can identify your most reliable and least reliable suppliers and make more informed procurement decisions.

- With an accurate reorder point for each SKU, you’ll always have enough stock on hand to satisfy customer demand — without overstocking and tying up excess capital in inventory.

- Sourcing decisions—deciding which suppliers to use—are generally made periodically.

Get pricing below and learn more about why thousands of brands work with ShipBob’s ecommerce fulfillment services. “So many 3PLs have either bad or no front-facing software, making it impossible to keep track of what’s leaving or entering the warehouse. We know it can be challenging to keep track of all these formulas, so we decided to create a handy Inventory Formula Cheat Sheet with 7 of the most common formulas. If you have at least one procurement cycle and one sales cycle worth of data.

Marketing (feature personalized ads)

Conversely, If you order too late (as we saw with Hershey’s), you’ll run out of stock. It’s a retailer’s nightmare scenario to have customers that are primed to buy but can’t due to inventory management errors. It can frustrate customers to the point where they stop doing business with you and go running right to your competitor’s door. You can use forecasting tools to predict needs and ensure you can meet demand and replenish stock efficiently. Using the reorder point formula will help you calculate these critical metrics and keep your customers satisfied.

The Reorder Point Formula

If a company knows it only needs to order inventory once per month, it can order larger quantities each time, which can lead to discounts from suppliers. Open to buy (OTB) is a term used in the retail industry to describe the amount of money that a retailer has available to spend on inventory. It is calculated by subtracting the projected cost of goods sold from the current inventory levels.

ShipBob keeps reorder points simple

- Manufacturers’, distributors’, and wholesalers’ inventory tends to cluster in warehouses.

- Delivery times can vary based on your order quantity (larger orders could take longer to ship).

- Read this section, which will help you understand how companies keep and manage inventory.

- Working with dozens or hundreds of spreadsheets can be time-consuming and error-prone for growing retailers, manufacturers, or wholesalers.

- By using the reorder point formula, you know that when your inventory reaches 175 red bandanas, you need to replenish your inventory so you don’t experience shortages.

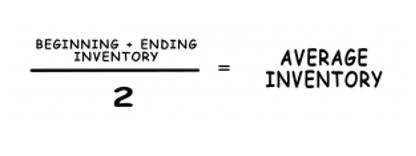

ShipBob’s cutting-edge inventory management software and analytics tools make it easier than ever. Lead time is the number of days between when you place a purchase order with your manufacturer or supplier for a product and when you receive the product. Your lead time for getting new stock will be longer if your supplier is overseas as compared to a domestic or in-house production facility. Add which one of these would not be a factor in determining the reorder point? the total delivery time (15 days ) and divide it by the number of orders (3).

How to use the reorder point formula in your business

- This may seem prudent on its face, but when you study your cash flow statement and see how much money ties up in stock, you realize how detrimental it is to your profitability.

- Dell can more easily return the parts to its suppliers if at some point it redesigns its computers to better match what its customers want.

- It improves inventory operations, avoids stockouts, and maintains ideal inventory levels.

- So now you know the reorder point formula, but you might be wondering – what is demand during lead time?

- Consistently running out of stock is certainly not a desirable way to engender customer trust.

- Therefore, in order to be a successful and profitable company, inventory management must be managed wisely.

While our skateboard shop was a hypothetical example, let’s take a look at a real-world example of how messing up reorder points can cause devastating ripple effects to your business. https://www.bookstime.com/ A broken supply chain crushed Hershey’s Halloween sales one year when they miscalculated their inventory reorder metrics. They were unable to meet retailers’ lead times and had a ripple effect that hurt store sales. Now that you know how to calculate reorder points for your products, let’s go over some frequently asked questions regarding reorder points. The reorder point is calculated by taking into account average daily sales, lead times, and safety stock. For this reason, inventory management is a very important part of core operations activities.

Categories:

Categories:  Tags: |

Tags: |